ABOUT US

Tube

INTRODUCTION

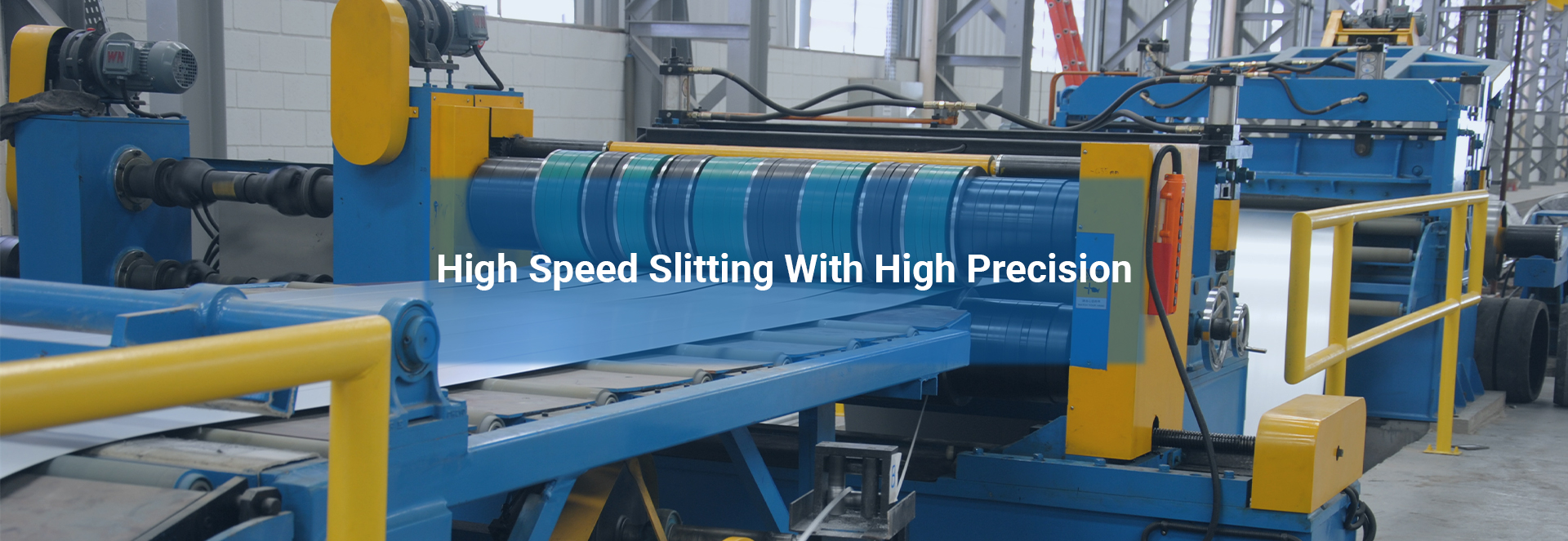

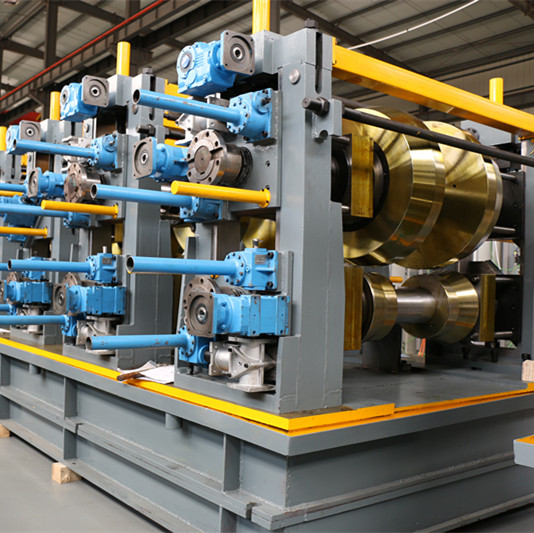

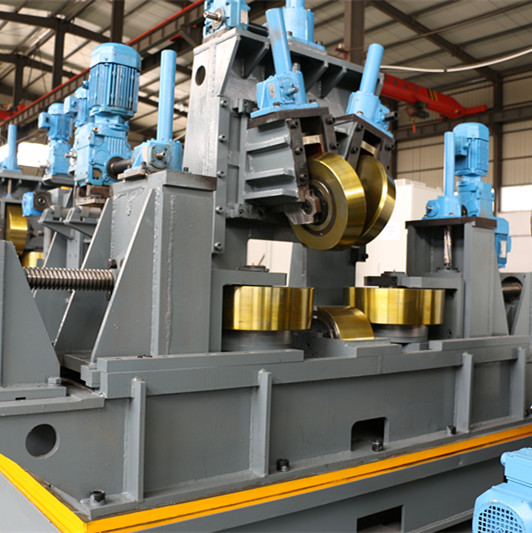

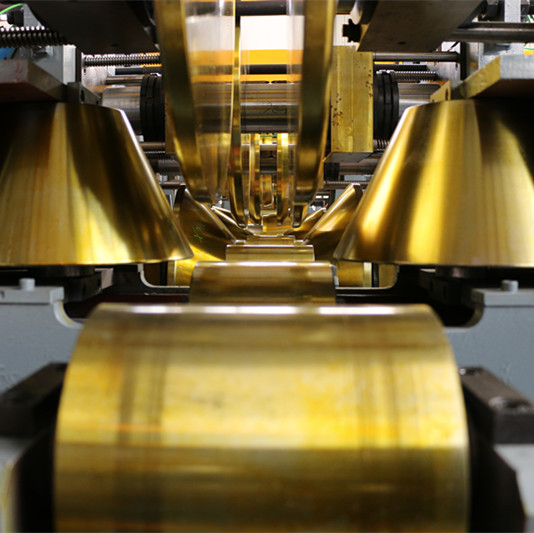

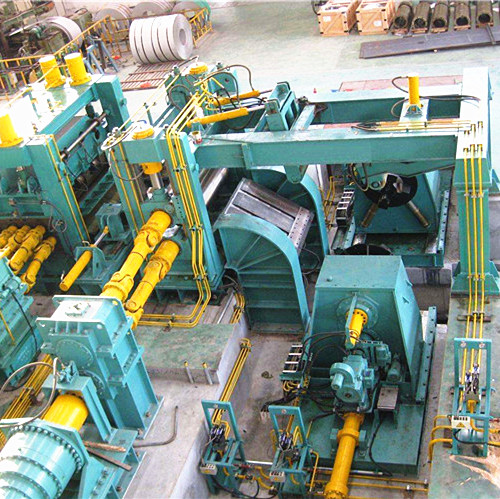

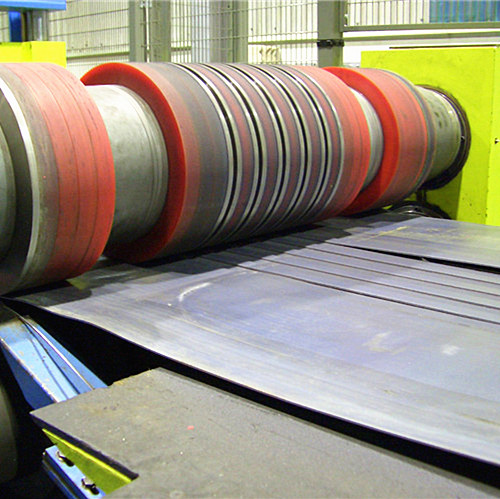

Hebei TUBO Machinery Co., Ltd. manufactures welded ERW Tube Mill / Pipe Mill, LSAW (JCO) Pipe Mill, Cold Roll Forming Machine and Slitting Line, as well as auxiliary equipments for more than 15 years, we developed and grew in line with constantly evolving market requirements.

With morden design software and more than 130 sets all types of CNC machining equipments, TUBO Machinery has been continuously developing and reinforcing its know-how in the field in time.

-

-15 years experience

-

-CNC Machining Equipments

-

-+More than 80 products

-

-$More than 2 billion

products

Our Products

NEWS

Service First

-

Cold Roll Forming Production Line to Argentina

Cold Roll Forming Production Line is using the cold roll forming technology to produce various shapes of section steels; mainly used in producing steel sheet piles, steel structure C, Z Purlin; Floor boards and roofing ,wall panels transport industry ,high-speed highway guardrail plate;automotiv...

-

Automatic Packing Machine to Colombia

Automatic Packing Machine This equipment is suitable for ERW89 pipe machine. Max Length of steel pipe :8m It's a Packing equipment designed especially for steel pipe industry, It is used to coll...